High purity Potassium(Sodium)Ethyl Xanthate supplier - Flotation collectors for sulfide ores

- Model

- Potassium(Sodium) Ethyl Xantahte: 90%min

Item specifics

- Categories

- Xanthate

- Product name

- Potassium(Sodium)Ethyl Xanthate

- Steel material

- Yellow

- Packing

- 25kg or 40kg/plastic woven bags,110kg/steel drum,

- Loading

- 18mt/20fcl

- OEM Packing

- accepted

- CAS No.

- 140-89-6/140-90-9

- Delivery time

- within 20 days after payment receipt

- Free sample

- yes

Review

Description

What is Potassium(Sodium)Ethyl Xanthate

Potassium/Sodium Ethyl Xanthate is a chemical reagent primarily used as a collector in the froth flotation process for extracting sulfide minerals (e.g., copper, lead, zinc, and gold ores).

Core Features

1.Chemical Type: Organosulfur compound (alkyl xanthate)

2.Primary Use: Collector for sulfide ore flotation (Cu, Pb, Zn, Au)

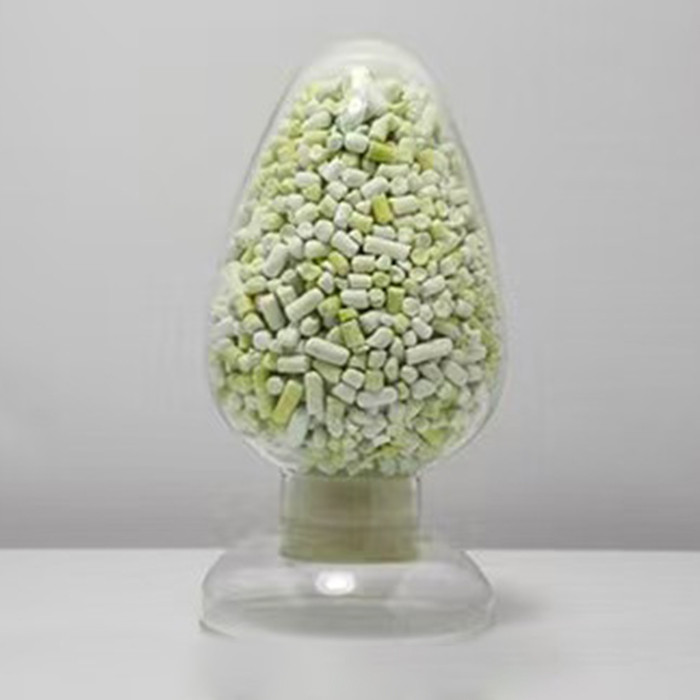

3.Physical Form: Pale yellow powder/granules (water-soluble)

4.Key Properties: Selective adsorption on sulfide mineral surfaces, Decomposes when heated (releases toxic CS₂ gas), Stable in alkaline conditions

5.Industrial Advantages:Cost-effective, Strong frothing capability, Widely used in large-scale mining operations

Potassium(Sodium)Ethyl Xanthate

High puritye:≥90% Ethyl Xantahte content

In various forms: granuler and powder

SPotassium(Sodium)Ethyl Xanthate specifications:

| Product: | Sodium Ethyl Xanthate | |

| CAS No.: | 140-90-9 | |

| Molecular Formula: | C₃H₅NaOS₂ | |

| Molecular Weight: | 144.18 | |

HS CODE: | 293090 | |

Properties: | Solid | |

Specifications: | 90% | |

Items | Unit | Specifications |

Sodium Ethyl Xantahte | %,≥ | 90 |

Free alkali | %,≤ | 0.2 |

Moisture & Volatil | %,≤ | 4 |

D | mm | 3~6 |

L | mm | 5~15 |

Product display:

Ethyl Xanthate Collector

Ethyl Xanthate Mining Flotation

Mining Chemicals Ethyl xanthate

Application

As a collector,the selectivity of sodium ethyl xanthate is the most strong in xanthate line.It is widely used in the preferential flotation of readily floatable minerals or complex

sulfide minerals.It is also used in the flotation of copper,lead oxide ores in conjunction with vulcanizing agents.It is also used as precipitant in hydrometallurgical processes

(eg.the refining of zinc electrolyte)and as sulfidation promoter of rubber.

Applications & Solutions

Mining flotation

Sulfide ore collection, priority flotation (separation of multiple sulfide ores), mixed flotation (recovery of total sulfides)

Rubber industry

Vulcanization accelerator

Wastewater treatment

Heavy metal precipitant

Related Product

Forging (Rolling) Steel Balls: OEM/ODM solutions & wholesale supply for global brands.

High Chrome Cast Grinding Balls - Premium wear-resistant grinding media for mining and cement industries.

Grinding Cylpebs: OEM/ODM solutions & wholesale supply for global brands.

Sodium Metasilicate Pentahydrate OEM/ODM solutions & wholesale: Used for Detergents and soap,

FAQ

What are Potassium/Sodium Ethyl Xanthate particles? What are the main components and characteristics?

Potassium Ethyl Xanthate (PEX, C₃H₅KOS₂) and Sodium Ethyl Xanthate (SEX, C₃H₅NaOS₂) are organosulfur compounds formulated as solid particles (powder or granules),

primarily used as collectors in sulfide mineral flotation.

· Appearance: Pale yellow to orange particles (powder/granules)

· Odor: Pungent (rotten cabbage-like, due to CS₂ potential)

· Stability: Decomposes in acid/heat → Releases toxic CS₂ gas

Is granular Ethyl Xanthate better than powder for flotation use?

Granular ethyl xanthate is generally preferred over powder for industrial flotation due to safer handling (less dust/CS₂ exposure), better moisture resistance, and steadier

dissolution, though powders offer faster initial action. Choose granules for stability in large-scale operations or powder for rapid dosing in dynamic circuits - performance

differences are minimal if properly dissolved.

Is 90% ethyl xanthate better in use and transportation than other contents?

90% ethyl xanthate is generally superior for both industrial use and transportation compared to lower purity products, offering higher active content for more efficient dosing,

better flotation performance consistency, and improved storage stability. While it comes at a slightly higher cost, these advantages typically outweigh the price difference.

The higher purity formulation does require more careful handling during transport due to increased CS₂ gas emission risks when exposed to moisture or heat, necessitating

proper sealed packaging and temperature control. For most mining applications, the operational benefits of 90% purity justify its selection, though lower grade

alternatives (80-85%) may be considered for simpler ore processing where cost is the primary concern.