High Purity Magnesium Oxide White Granular - OEM & ODM Manufacturing

- Model

- 65%

Item specifics

- Item

- Magnesium Oxide

- Packing

- PP+PE 25/50 net

- HS code

- 2519909100

- Molecular Weight

- 40.31

- Certificate

- ISO, SGS, CIQ, CCIC, Intertek

- Application

- Industrial, Fertilizer, Feed

Review

Description

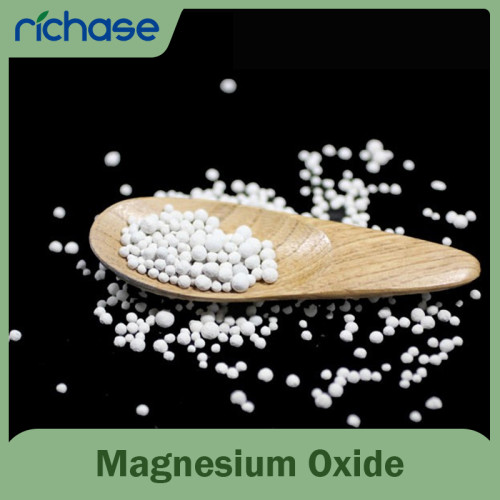

Magnesium Oxide White Granular

Magnesium oxide (MgO), or magnesia, is a white hygroscopic solid mineral that occurs naturally as periclase and is a source of magnesium (see also oxide). It has an empirical formula of MgO and consists of a lattice of Mg2+ ions and O2− ions held together by ionic bonding. Magnesium hydroxide forms in the presence of water (MgO + H2O → Mg(OH)2), but it can be reversed by heating it to separate moisture.

Core Features of Magnesium Oxide White Granular: Key Benefits for Global Miners

1. Unmatched Purity for Enhanced Recovery

Sourced from China’s most abundant magnesite deposits, it boasts 99.5%+ purity (with low iron/silica impurities). This minimizes contamination in ore beneficiation, boosting metal recovery rates by 3-5% compared to lower-grade MgO—key for gold, copper, and lithium mines.

2. Stable Granulation for Consistent Performance

Advanced spray-drying and granulation tech produce uniform 0.5-2mm white granules. Unlike powders, they resist bridging in hoppers, reduce dust, and ensure even distribution in mills—eliminating batch variability that plagues miners.

3. Versatile Adaptability Across Applications

Tailored for ore beneficiation (neutralizing acidic ores), grinding media (reducing mill wear), and smelting flux (stabilizing slag). Miners report faster settling times, longer equipment life, and lower energy use in their operations.

4. Cost-Efficiency Without Sacrificing Quality

Leveraging China’s vertical supply chain, we deliver premium MgO at 20% lower costs than European/Southeast Asian rivals—critical for mines optimizing operational budgets.

Richase’s Magnesium Oxide White Granular: Pure, reliable, and built for mining success.

Why Choose Our Magnesium Oxide Gray Granular?

1)Main Content is high, raw material ore is widely and quality good.

2)Price is competitive, our plant is located in the richest magnesium ore in china

3)Shipment is fast, large production capacity

4)Production technology isstable and advanced.

5)Technical support from technical talents

B2B Focus: Tailored for manufacturers, wholesalers, and industrial buyers.

Competitive Pricing: Direct factory supply with MOQ flexibility.

Certified Quality: ISO-compliant, with SGS/ROHS testing reports.

Product Display

buy magnesium oxide powder

magnesium oxide powder

buy magnesium powder

Ferrous sulphate monohydrate granular specifications

| Product | FERROUS SULPHATE MONOHYDRATE | |||

| CAS No. | 13463-43-9 | |||

| Molecular Formula | FeSO4.H2O | |||

| Molecular Weight | 151.9 | |||

HS CODE | 28330910 | |||

Properties | Solid | |||

Specifications | ||||

Items | Unit | Specifications | ||

Purity as FeSO4.H2O | %,approximate | 91 | ||

Purity as Fe | %,approximate | 30 | ||

Lead (Pb) | mg/kg,max | 20 | ||

Arsenic (As) | mg/kg,max | 2 | ||

Application

1)Agricultural Applications & Fertilizer Use

Ferrous sulfate monohydrate is widely used in agriculture as a source of iron fertilizer to enrich soil with iron. It helps improve photosynthesis and plant growth, particularly in soils suffering from iron chlorosis.

2)Animal Feed & Healthy Animal Feed Blocks

Ferrous sulfate monohydrate is used as an animal feed additive to provide essential iron, especially for animals with iron deficiency, such as poultry and swine. Iron is a critical component of hemoglobin in animal blood, and its deficiency can lead to anemia.

3)Industrial Applications

In industrial applications, ferrous sulfate monohydrate is widely used in water treatment, wastewater treatment, and soil remediation. It effectively removes heavy metal ions from water, particularly when treating water and soil contaminated with excessive heavy metals, due to its strong precipitation properties.

4)Other Uses

Ferrous sulfate monohydrate is also used as an iron source in food additives, lawn fertilizers, and certain reactions in fertilizer production. It is also employed in the production of certain chemicals, particularly in corrosion protection in the steel industry and in the manufacture of bleaches.

Applications & Solutions

Agriculture

Soil amendment, fertilizer additive, iron deficiency prevention

Industrial

Water treatment (phosphorus removal), wastewater clarification

Pharma/Lab

Chemical reagent, pharmaceutical intermediate

Environmental

Pollution control, ecological restoration

Storage Environment Requirements

✦Key Requirements:

Store in dry, sealed containers (humidity <45%) to prevent moisture absorption

Max 3-pallet stacking height for optimal bag integrity

Keep away from acids/chlorides (min. 2m distance)

Use PE-lined containers for sea transportation

✦Our Advantages:

Pre-dried packaging with moisture indicators

Dust-proof design for cleaner handling

Custom RFID tracking available for bulk orders

Related Product

Ferrous Sulphate Monohydrate Granular: OEM/ODM solutions & wholesale supply for global brands. High purity for enhanced performance.

High-quality Magnesium Oxide Gray Granular (MgO) – ideal for refractory, steel, and rubber industries. Our premium-grade mag oxide offers high purity, thermal stability & bulk supply options. Trusted by global B2B buyers.

High Chrome Cast Grinding Balls - Premium wear-resistant grinding media for mining and cement industries. Our OEM/ODM solutions offer superior hardness (58-65 HRC) and toughness through optimized casting technology. Ideal for ball mills with 30% lower wear rate than standard balls. Global wholesale supply available.

Ferrous Sulphate Monohydrate Granular: OEM/ODM solutions & wholesale supply for global brands. High purity for enhanced performance.

FAQ

What is the typical purity level of your Magnesium Oxide Gray Granular?

Our Magnesium Oxide Gray Granular is available in 95-98% purity grades, with strict control of impurities (CaO<1.5%, SiO₂<0.5%). Higher purity options (99%+) can be customized for refractory applications.

How does your product compare to powdered MgO in steelmaking?

The granular form offers:

✔ Lower dust pollution - improves workshop safety

✔ Controlled dissolution rate - better slag conditioning

✔ Higher yield - reduces material loss by 15-20% vs. powders

Can you provide technical support for refractory design?

Yes! Our engineers offer:

• Free formula optimization based on your kiln conditions

• Lab test reports (thermal shock/compressive strength)

• Trial batch production before mass orders