Premium Chlorinated Polyethylene (CPE) for Industry - Global OEM Supplier

- Model

- 135A

Item specifics

- Categories

- Chlorinated polyethylene

- Product name

- CPE

- Color

- white

- Packing

- 25kg PP/PE neutral bag

- OEM Packing

- accepted

- CAS No.

- 63231-66-3

- Delivery time

- within 20 days after payment receipt

- Free sample

- yes

Review

Description

What is Chlorinated polyethylene

Chlorinated Polyethylene (CPE) is a polymeric elastomer material produced by chlorinating high-density polyethylene (HDPE). The product appears as a white powder, non-toxic and odorless. CPE exhibits excellent toughness, oil resistance, flame retardancy, colorability, and chemical resistance. It is compatible with various plastics and rubbers and possesses outstanding filling properties. Depending on its specific characteristics, CPE can serve as an impact modifier for PVC or as a rubber-type chlorinated polyethylene.

Core Features in Rubber & Plastic

1.As an effective impact modifier for polyvinyl chloride (PVC): Unmodified rigid PVC products (such as pipes and profiles) exhibit poor impact resistance, particularly prone to brittle fracture at low temperatures. Adding CPE significantly enhances the notch impact strength of PVC.

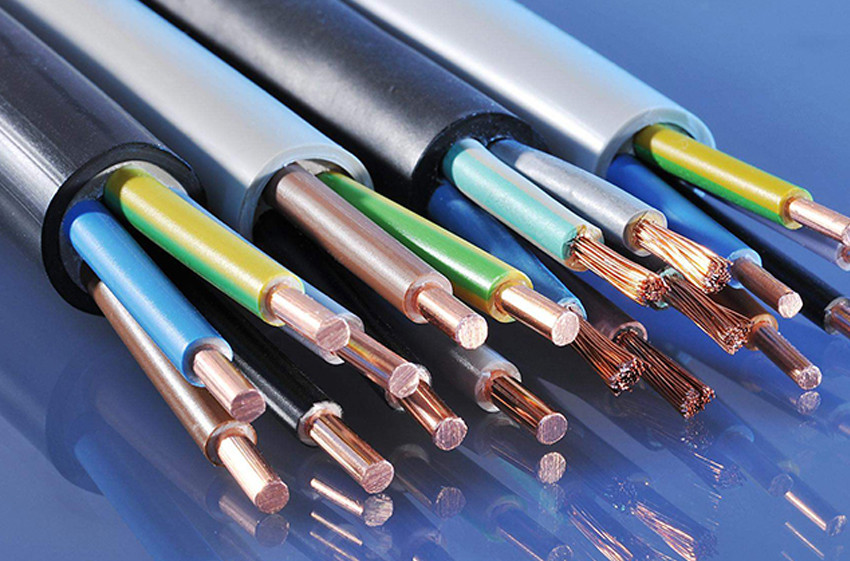

2.Used for manufacturing flame-retardant, weather-resistant specialty plastics and wire/cable compounds: CPE inherently contains chlorine elements, providing flame-retardant properties. It can be blended with other plastics (such as PE, PP, EVA, etc.) to produce flame-retardant, weather-resistant composite materials.

3.Toughening through blending with polyolefins (e.g., PP/PE): CPE can also be used to toughen polypropylene (PP) and polyethylene (PE), particularly in recycled material modification. It enhances the low-temperature toughness and impact resistance of these materials.

4.As a PVC processing aid (as a substitute or supplement to ACR): CPE can also improve PVC melt strength and plasticization rate to some extent, helping materials melt more uniformly and reducing melt fracture, thereby enhancing surface finish.

Chlorinated polyethylene

Chlorinated Polyethylene (CPE) is a polymer made from high-density polyethylene (HDPE) via chlorination. Its key properties include excellent weather resistance, flame retardancy, oil resistance, flexibility, and chemical resistance, and it is non-toxic and environmentally friendly.

CPE primarily belongs to the chemical industry, more specifically to the polymer chemistry or fine chemicals sector under the plastic and rubber additives industry. It is an important polymeric material additive

Chlorinated polyethylene:

| Product: | Chlorinated polyethylene | |

| CAS No.: | 63231-66-3 | |

| Molecular Formula: | [CH2-CHCl-CH2-CH2]n | |

| Molecular Weight: | ||

HS CODE: | 3901909000 | |

Properties: | powder or granules | |

Specifications: | ||

Items | Unit | Specifications |

Peel Strength, ≥N/m | 90 | |

Volatile, ≤% | 1.2 | |

Appearance | Milk white chips | |

Product Display:

CPE for plastic profiles

Chlorinated PE wire and cable

Chlorinated Polyethylene for PVC

Application

Chlorinated polyethylene resin is a novel synthetic material with a range of outstanding properties. It serves as an excellent impact modifier for PVC plastics and also functions as a synthetic rubber with well-rounded performance characteristics. Its applications are exceptionally broad, having been widely adopted in products such as cables, wires, hoses, rubber sheets, rubber and plastic goods, sealing materials, flame-retardant conveyor belts, waterproof membranes, films, and various extruded profiles.

CPE can also be blended with polypropylene, high/low-density polyethylene, ABS, and other plastics to enhance their flame retardancy, aging resistance, and printability. CPE can be regarded as a random copolymer of ethylene, polyethylene, and 1,2-dichloroethylene. Its molecular chain is saturated, with polar chlorine atoms randomly distributed. Due to its outstanding physical and chemical properties, it is widely used in machinery, power, chemical, building materials, and mining industries. CPE exhibits superior heat resistance, ozone resistance, weather resistance, and aging resistance compared to most rubbers.

Its oil resistance surpasses nitrile rubber (NBR) and chloroprene rubber (CR), while its aging resistance exceeds that of chlorosulfonated polyethylene (CSM). It resists corrosion from acids, alkalis, and salts, is non-toxic, flame-retardant, and non-explosive.

Primary applications include:

Electrical wires and cables (including mining cables and wires specified in UL and VDE standards), hydraulic hoses, automotive hoses, belts, sheets, modification of PVC profiles and pipes, magnetic materials, ABS modification, etc.

Applications & Solutions

automotive and rubber industrie

PVC clip-on panels

PVC Cable Protective Sleeve

PVC water pipe

Related Product

Titanium dioxide: OEM/ODM solutions & wholesale supply for global brands. High purity for enhanced performance.

Magnesium Sulphate Heptahydrate Crystal MgSO4.7H2O Feed Grade with good price.

Magnesium Sulphate Monohydrate Powder MgSO4 Feed Grade with good price.

FAQ

What are the characteristics of CPE?

1. CPE is a saturated rubber exhibiting excellent resistance to thermal-oxidative aging, ozone aging, acids, alkalis, and chemicals.

2. Containing chlorine elements, CPE possesses outstanding flame-retardant properties and exhibits non-dripping characteristics during combustion. When appropriately blended with antimony-based flame retardants, chlorinated paraffin, and AL(OH)₃, it yields flame-retardant materials with superior performance and low cost.

3. CPE is non-toxic, free of heavy metals and PAHs, and fully compliant with environmental regulations.

4. CPE exhibits high filler compatibility, enabling the production of products meeting diverse performance requirements.

How does CPE significantly improve the processing rheology of plastics such as PVC?

CPE acts as an internal lubricant and melt promoter through its unique elastomeric properties. Its molecular chains are partially compatible with PVC, enabling it to function as a "bridge"between PVC particles and effectively transmit shear forces, thereby:

1.Promote melting: Reduce PVC melting temperature, accelerate melting speed, and save energy consumption.

2.Improve melt strength: Reduce melt fracture, enhance surface finish, and eliminate the “shark skin”effect.

3.Optimizing rheological behavior: Enhancing the melt viscosity's sensitivity to shear rate, thereby improving flowability under processing shear while maintaining shape stability at low shear rates. This significantly benefits processes such as extrusion and calendering.

What makes CPE a superior impact modifier compared to other additives for rigid PVC applications?are the key properties of Neoprene?

CPE is favored for its unique combination of impact enhancement, weather resistance, and processing aid functionality. Unlike some modifiers that only improve toughness, CPE simultaneously:

Provides excellent low-temperature impact strength.

Imparts superior resistance to UV light and weathering, crucial for outdoor profiles.

Acts as a processing aid, improving melt flow and surface quality.

This multifunctional nature often eliminates the need for additional additives, simplifying formulations and offering a compelling cost-performance balance.