Copper Mining Efficiency Gains Traction with Advanced Grinding Media and Reagents

- Share

- publisher

- 、Saskia

- Issue Time

- Aug 1,2025

Summary

Copper miners are optimizing operations with high-performance grinding media and flotation reagents. Discover how these innovations reduce costs and boost recovery rates.

Copper Mining Efficiency Gains Traction with Advanced Grinding Media and Reagents

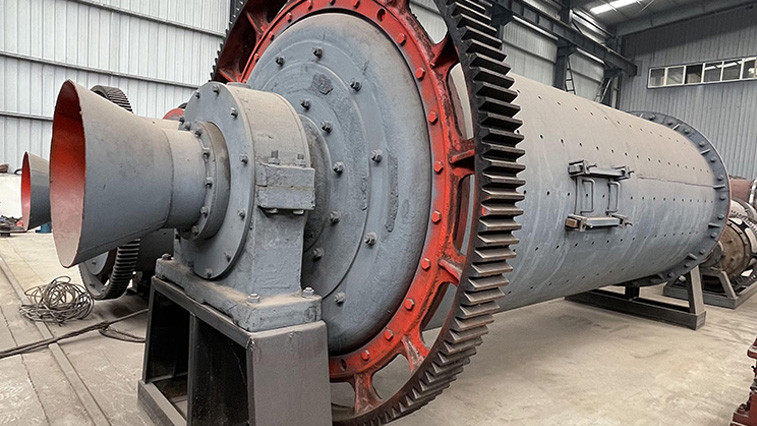

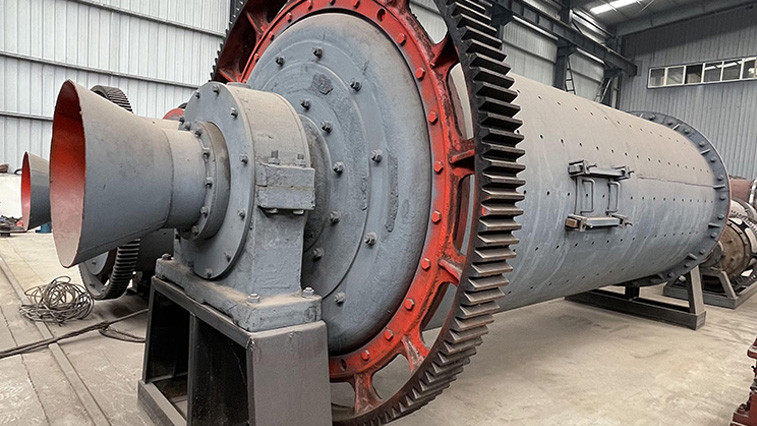

As the world needs more and more copper, mining companies are trying to get better at making this copper using fewer resources and more efficient processes. The key to getting the most out of this machine is using two important materials: grinding media balls and mining chemicals

The grinding circuit, often the plant's largest energy consumer, benefits directly from high-hardness, low-wear grinding media balls. Superior balls minimize consumption and power usage per ton of ore processed, directly impacting the bottom line. Subsequently, in the flotation circuit, the performance of specialized mining chemicals, such as collectors and frothers, is paramount. These reagents determine the final recovery rate and concentrate grade of copper, turning marginal ore into profitable resources.

For mine managers, choosing which supplier to use is an important decision. By working with advanced manufacturers like Richase, who provide high-performance grinding media and flotation reagents, we can ensure a reliable supply of essential products, which helps keep our plants running smoothly and makes sure we can make a profit in the long term.

Whether you’re in need of a reliable flotation collector for sulfide ores or a consistent potassium/sodium ethyl xanthate supplier, Richase is your dependable partner—offering quality, consistency, and customized solutions to support your mineral processing goals.