Enhancing Plastics with MgO Solutions

- Share

- publisher

- 、Saskia

- Issue Time

- Oct 15,2025

Summary

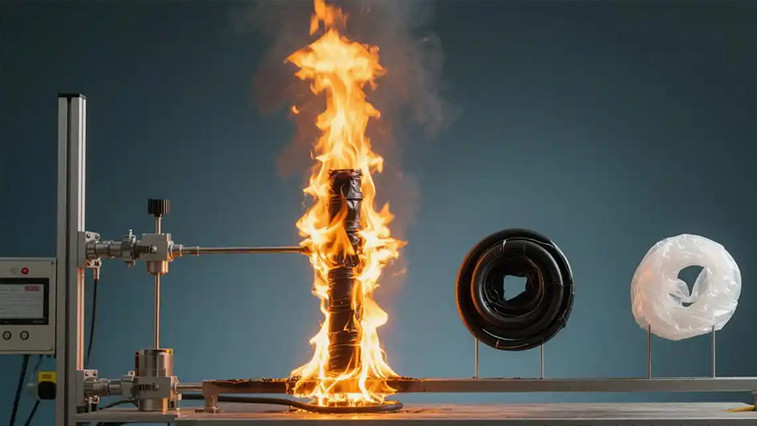

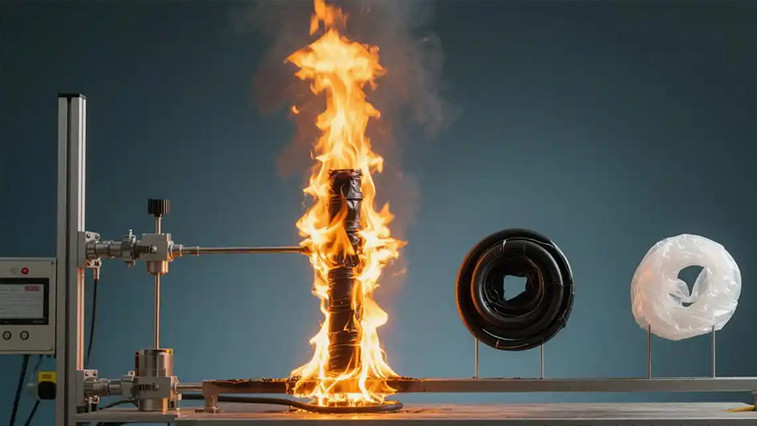

MgO enhances flame resistance in rubber, reducing fire hazards and improving safety in industrial applications.

Magnesium Oxide as Flame Retardant in Rubber

Magnesium oxide (MgO) is a key flame retardant additive in rubber manufacturing. Its high thermal stability and endothermic decomposition absorb heat, delaying ignition and suppressing smoke. This makes it ideal for industrial materials like conveyor belts, seals, and cables where fire safety is critical. Richase’s high-purity MgO ensures consistent performance, meeting stringent safety standards.

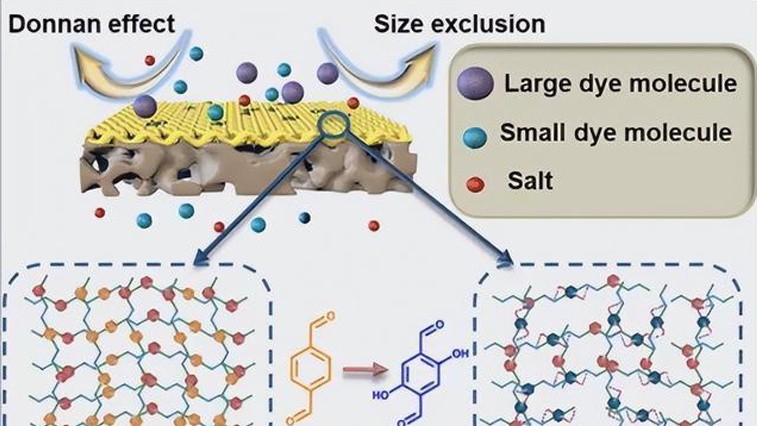

In comparison to traditional calcium carbonate filler, MgO offers superior fire resistance without compromising mechanical properties. Its synergy with polymer additives like alumina trihydrate enhances retardancy. For plastic modification, MgO also improves thermal stability, making it a versatile choice across industries.

For optimal results, combine MgO with complementary additives t o balance flame resistance and elasticity. Consult our technical team for custom formulations.

[Platform release disclaimer]

This platform part of the article picture source or adapted from the Internet, the main purpose is to share information, so that more people get the information they need, the copyright belongs to the original author, such as infringement of your rights and interests or copyrights, please let us know in time, we will be deleted within 24 hours!